Van Tienhovenmolen

Last week I had the opportunity to tour and learn all about Van Tienhovenmolen - a historic windmill in the province of Limburg. Unlike a lot of windmills in the Netherlands, even ones that turn for tourists, this one has been fully restored and is actually used to produce local, organic flour among other products.

My tour guide, Belinda, recently passed the national millers exam for wind and water mills which is a huge accomplishment. I was enthralled learning about the mill from the ground up and of course I wanted to share my experience with you!

A little history first. Since 1957 the mill has been owned by the Limburg Landscape foundation. It was originally crafted in 1855 (coincidentally, the same year my great-great grandparents built the house I grew up next to) and is the only mill in the Netherlands built entirely out of Marlstone. In 1922 the mill burned, except for the stone. It’s rumored that the mill was set fire by the owner to collect insurance money, however, it was never investigated.

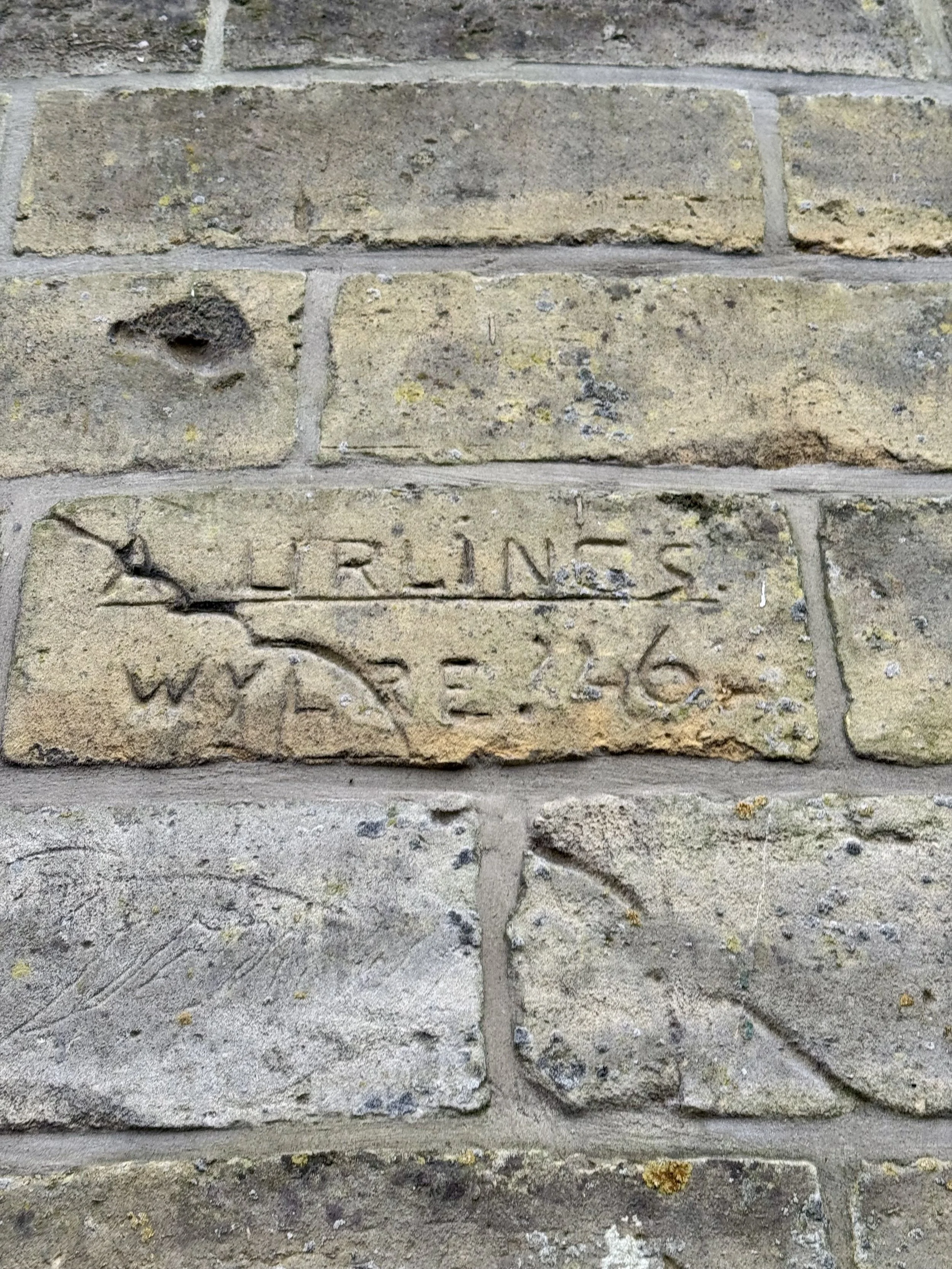

By 1923 the mill was operational again and ran until 1939. During World War II it was used at an outpost and lookout. You can still see some of the carvings left behind from the soldiers that were there. Located at the top of a plateau, it would have been a excellent lookout spot and the windmills wings were even used as a signaling tool. Below are some of the carvings and also some remaining burn damage - when Marlston reaches a high temperature, it turns red as you can see in the picture below.

Today the mill is leased by Koen van der Matt who mills with volunteers to produce the flours for sale in their shop. It’s beautiful to see this windmill come full circle and once again be used for its original purpose, especially in an age where items like flour and grains are generally mass produced and cheaply made. As a bread baker myself, I have learned the difference high quality ingredients can make in the finished products.

The concept of a mill is fairly simple: the sails turn a shaft that is attached to a wheel with tines and those tines are connected to another wheel that turns a stone. That second wheel can be attached or detached, as necessary, depending on if the stone needs to be engaged (milling) or not. There are a few more pieces to it, but that’s the general idea, at least for our purposes here.

Belinda set the brake on the sails, so I could take a full tour all the way to the top floor. The mill was not operational that day due to low winds. In fact, they unfortunately had about two weeks of minimal operation due to lack of wind.

Side note: I found it fascinating that this device is how they move the sails to the direction of the wind. One person can move the entire top of the windmill with this pulley, hand crank device and the chains. This is amazing because the cap that turns weights around 20,000 kilograms! In fact, the entire top isn’t attached to the stone, rather it rests on the top. I knew that modern wind turbines had the ability to turn into the wind., but I had no idea that the old ones did as well. The engineering that went into these windmills starting in the 1200’s is truly mind blowing.

Once inside, I started the tour all the way at the top. Five flights up to be exact, where the cap is and the sail shaft comes through. When mills were first constructed by the Dutch the 1200’s, all the parts would have been made out of wood. Today there are many parts that are made out of cast iron, however, a large portion of the mechanical parts are still wood because it’s easier to repair and replace those items.

The cap sits on wheels that move when the pulley device is used to change the direction of the sails. They use fat from the belly of a pig (stored in the top floor - picture below) along with beeswax as lubricant for the moving parts. The sustainability and low impact on the environment every step of the way is impressive.

From here there is basically two flights of vertical shaft going down to the mill stone. The stones weigh about 1600 kilograms are specially built and must be meticulously maintained. The grain goes in the center of the stone and is ground as it is pushed out by centrifugal force. There are various adjustments the miller can make, however, if the wind is too strong or too weak, it will likely be impossible to mill.

The milled grain comes out on the floor below the stones and in the final process is bagged and weighed. In addition to flour, they have bread and cake mixes, cookie and pancake mixes and baking related items in their shop.

As a bread baker, of course, I had to go home with some of their products. I selected three different types of flour and am looking forward to trying them all. The first baguettes I made were from their multigrain flour and turned out simply amazing (picture below). I also picked up a couple of the cake mixes and look forward to enjoying those soon.

The mill is currently open for tours and guests on Friday and Saturday. I highly recommend it and, of course, if you’re looking for a guided tour of the Limburg area, which includes many outstanding wineries and breweries as well, I would be happy to take you!

Cheers!